© 2025 ALL RIGHTS RESERVED. IB-CADDY D.O.O.

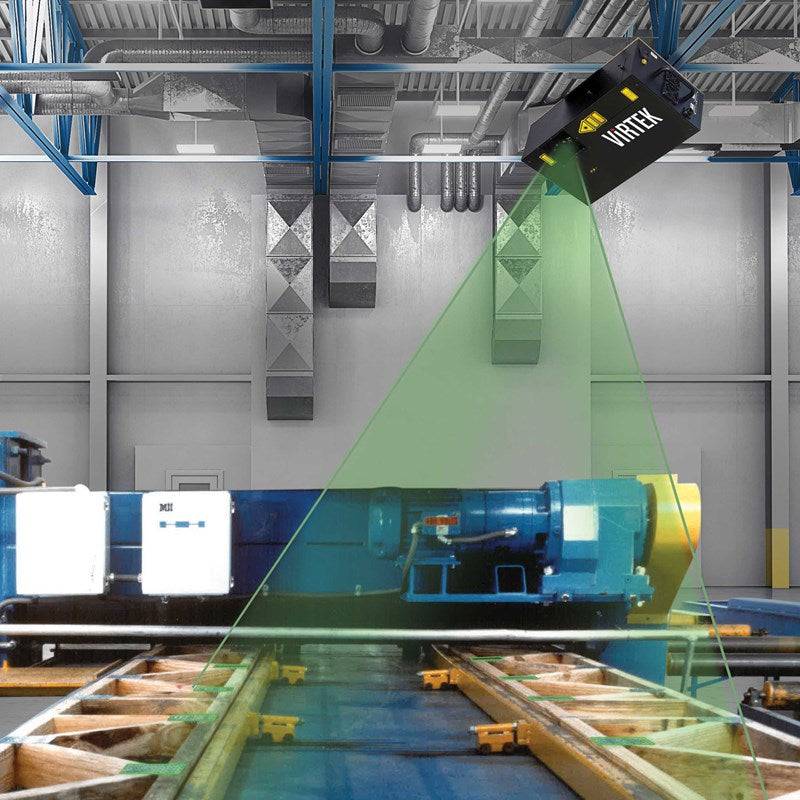

VIRTEK je globalni proizvajalec sistemov za lasersko projiciranje in kontrolo kakovosti.

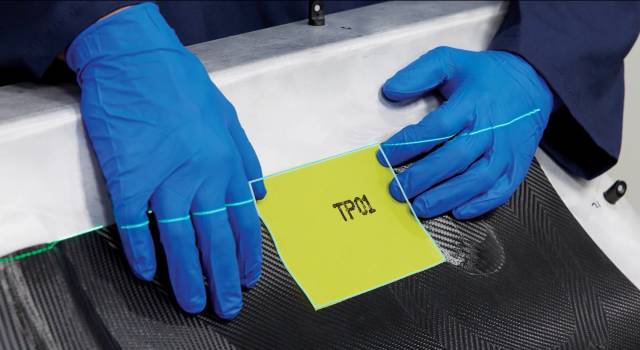

Sistem projicira visoko natančno virtualno lasersko predlogo, ki vodi operaterje pri sestavi 2D delov, s čimer popolnoma odpravlja potrebo po načrtih in ročnih meritvah.

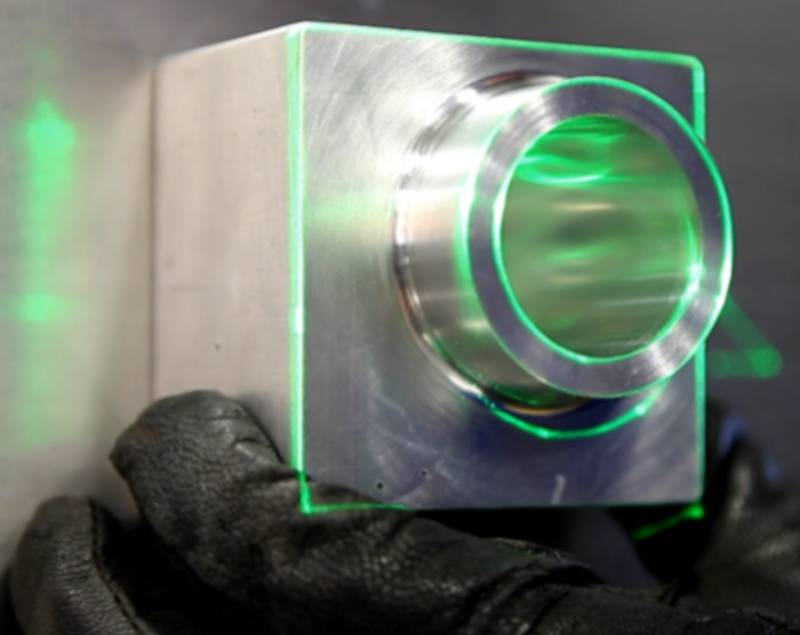

Napreden sistem laserske projekcije natančno prikaže virtualno predlogo na kompleksnih 3D kosih ali izdelkih in vodi operaterje skozi vsak korak izdelave in montaže.

Uporabniku prijazen sistem za kontrolo v realnem času, ki uporablja laserske žarke za merjenje natančnosti in kakovosti ravnih ter preoblikovanih delov. Hiter, zanesljiv in enostaven za uporabo.

Sistem za kotrolo, ki temelji na umetni inteligenci in računalniškem vidu, samodejno določi, ali je zaznana anomalija sprejemljiva ali ne. Natančno preverja manjkajoče nosilce, vijake, spoje in kompozitne komponente.

Pozicije se upoštevajo neposredno iz podatkov CAD modela in projicirajo z visoko natančnostjo na obdelovanec, kar zagotavlja točno, kot je zasnovano, postavitev vsakič.

S primerjanjem izdelka z načrtom, sistemi Virtek preprečujejo drage napake in ponovna dela, preden se zgodijo.

Potrebnih je manj monterjev in kontrolorjev, sistem pa takoj preveri napredek in natančnost, kar poenostavi delovni tok.

Sestavljalci vedno delajo z najnovejšimi CAD datotekami, brez čakanja tednov na posodobljene predloge ali ročne prilagoditve.

Znižajte stroške in zamude pri proizvodnji zaradi fizičnih priprav ter poenostavite shranjevanje in logistiko.

Samo odprite delovni nalog, sistem takoj projicira predlogo. Začnite z montažo TAKOJ, prihranite čas in povečajte produktivnost.

Virtek IRIS 3D omogoča napredno lasersko projekcijo, ki vodi operaterje skozi vsak korak varilnega procesa, zagotavlja popolno poravnavo, natančnost in učinkovitost.