© 2025 ALL RIGHTS RESERVED. IB-CADDY D.O.O.

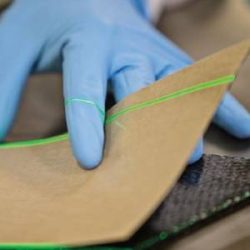

Laser templating and positioning systems accurately project a virtual laser template onto molds and parts to guide operators through the process of part fabrication whether it be ply layup, paint masking, assembly, or part placement.

Virtek Iris™ significantly advances laser-guided assembly with new integrated vision technology, innovative “FlashAlign” functionality, superior high visibility laserline and new multi-tasking capabilities, and thin-client experience boasts a unique offering.

Initial alignment is 20X faster and re-alignments are reduced from minutes to seconds – saving time, increasing workflow productivity, all while retaining quality and accuracy.

Part position is taken directly from CAD data and laser projected onto the workpiece for exact as-designed placement.

Decrease production expense and delays caused by using templates.

Eliminates differences between “as-built” and “as designed” because assemblers are always working with the most current CAD file.

Spatial Positioning System

The IRIS™ Spatial Positioning System combines the laser projection technology with 3D vision technology to locate a part in 3D space then quickly locks onto its CAD-specified assembly position. IRIS