© 2025 ALL RIGHTS RESERVED. IB-CADDY D.O.O.

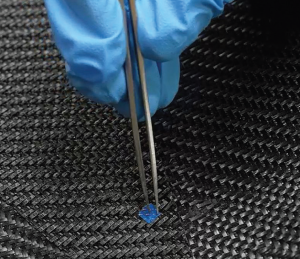

The next generation of quality inspection combines laser projection with artificial intelligence to deliver instant, reliable results. IRIS AI detects defects, missing components, and foreign-object debris (FOD) in real time, then guides operators precisely to the issue using laser projection.

Whether for panel inspection, composite manufacturing, or process monitoring, IRIS AI ensures unmatched accuracy within 1,6mm, full digital traceability, and effortless integration into your existing production workflow.

The new IRIS Ai-enabled Camera offers:

• Detailed reporting created for quality assurance

• Digital Data stored for permanent quality records

• Verify part process completion

• Capture data analytics for every single part built

Add on to existing Virtek Laser Projection Systems.